Introduction: What Is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process is widely used in various industries for its ability to produce complex parts with high precision and repeatability. From automotive to aerospace and medical sectors, CNC machining plays a vital role in shaping the modern industrial landscape.

Unlike manual machining, where a human operator controls the equipment, CNC machining automates the operation using coded instructions. This not only speeds up production but also minimizes errors and inconsistencies, making it ideal for both prototyping and mass production.

How CNC Machining Works

At its core, CNC machining transforms digital files into tangible parts. The process begins with a 3D model or a CAD (Computer-Aided Design) file. This file is converted into a CNC-compatible format using CAM (Computer-Aided Manufacturing) software. The software generates G-code, which the CNC machine interprets to perform precise cuts and movements.

CNC machines operate on multiple axes—typically 3, 4, or 5—allowing for intricate designs and tight tolerances. A standard 3-axis machine moves the tool along the X, Y, and Z axes. More advanced machines can rotate the tool or the workpiece, adding even more flexibility and efficiency to the process.

Types of CNC Machines

There are various types of CNC machines, each suited to specific tasks:

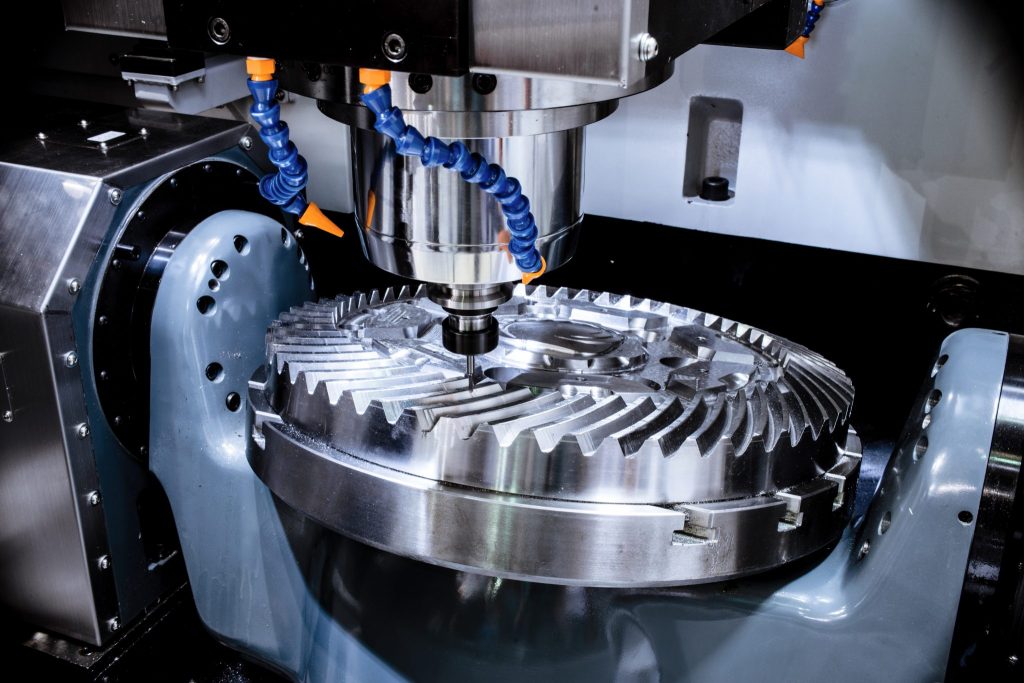

- CNC Milling Machines: These machines use rotating cutting tools to remove material from a workpiece. Ideal for producing complex parts, they are commonly used in automotive and aerospace industries.

- CNC Lathes: These operate by rotating the workpiece while stationary tools cut into it. Perfect for producing cylindrical parts like shafts, bolts, and bushings.

- CNC Routers: Used mainly for softer materials like wood, plastics, and aluminum, CNC routers excel in creating signs, furniture, and cabinetry.

- CNC Plasma Cutters: Use a high-powered plasma torch to cut through metal. They are often used in fabrication and construction.

- CNC EDM (Electrical Discharge Machining): Employs electrical discharges to shape hard metals into precise forms, often used in mold-making.

- CNC Laser Cutters: Utilize a focused laser beam to cut or engrave materials. Popular in both industrial and artistic applications.

Materials Used in CNC Machining

CNC machining supports a wide range of materials, making it highly versatile. Some commonly used materials include:

- Metals: Aluminum, steel, titanium, copper, and brass.

- Plastics: ABS, POM, PTFE, nylon, and acrylic.

- Composites: Carbon fiber, fiberglass.

- Wood: Hardwood, softwood, plywood, MDF.

The choice of material depends on the application’s requirements—such as strength, flexibility, heat resistance, and cost.

Applications of CNC Machining

CNC machining is integral to modern manufacturing due to its precision, speed, and reliability. Key industries utilizing this technology include:

1. Aerospace

Aircraft components require extremely tight tolerances. CNC machining is used to produce parts such as turbine blades, landing gear, and fuselage components.

2. Automotive

From engine blocks to dashboard panels, CNC machining enables the production of both functional and aesthetic parts in vehicles.

3. Medical

Medical devices must meet strict standards. CNC machining is employed to manufacture surgical tools, implants, and diagnostic devices with unmatched accuracy.

4. Electronics

CNC machines help in creating enclosures, heat sinks, and intricate parts for electronic gadgets and systems.

5. Defense

CNC machining plays a crucial role in producing weaponry, vehicle armor, and precision components for military applications.

Advantages of CNC Machining

The growing reliance on CNC machining is largely due to the many advantages it offers over traditional machining methods:

- Precision and Accuracy: Capable of producing parts with very tight tolerances.

- Repeatability: Ensures consistent quality across large production runs.

- Speed: Rapid production cycles with minimal manual intervention.

- Automation: Reduces the need for human operators and minimizes the risk of human error.

- Versatility: Can handle a wide range of materials and complex designs.

- Cost Efficiency: Especially beneficial for high-volume production and reducing material waste.

Challenges in CNC Machining

Despite its benefits, CNC machining has some challenges:

- Initial Cost: CNC machines and setup costs can be high.

- Skilled Labor: Operators need to understand both software and hardware to troubleshoot effectively.

- Material Waste: Subtractive nature of the process means excess material is removed, which can be costly depending on the material used.

- Complex Programming: Developing G-code for intricate parts requires specialized skills and experience.

Recent Innovations in CNC Machining

CNC machining continues to evolve with advances in software, automation, and integration with Industry 4.0. Some recent trends include:

- 5-Axis Machining: Allows for greater flexibility and more complex part geometries.

- AI Integration: Machine learning algorithms are being used to predict tool wear and optimize cutting paths.

- Cloud-Based Control: Operators can now monitor and control machines remotely.

- Hybrid Manufacturing: Combining additive (3D printing) and subtractive (CNC) processes in a single machine for greater efficiency.

CNC Machining vs. 3D Printing

While both CNC machining and 3D printing are used for part production, they have distinct differences:

| Feature | CNC Machining | 3D Printing |

| Process | Subtractive | Additive |

| Material Range | Broad (metals, plastics, etc.) | Limited (mostly plastics) |

| Surface Finish | Excellent | May require post-processing |

| Production Volume | Ideal for high-volume runs | Best for prototypes |

| Cost Efficiency | Costly for low-volume jobs | Cost-effective for small runs |

Both methods have their place in modern manufacturing, and many companies use them in tandem depending on the project needs.

Conclusion

CNC machining is an essential part of today’s manufacturing landscape. Its ability to produce highly accurate and consistent parts across a wide range of materials and industries makes it indispensable. From aerospace and automotive to medical and electronics, the impact of CNC machining can be seen everywhere.

While the technology does require a significant upfront investment and skilled operators, the long-term benefits far outweigh the challenges. With continued innovation and integration with AI and smart manufacturing, the future of CNC machining looks promising.

Whether you’re a manufacturer looking to scale production or an engineer developing a prototype, CNC machining offers a reliable, precise, and efficient solution.

Leave a comment